Corrosion le mochini o hananang le matla a koporo pad

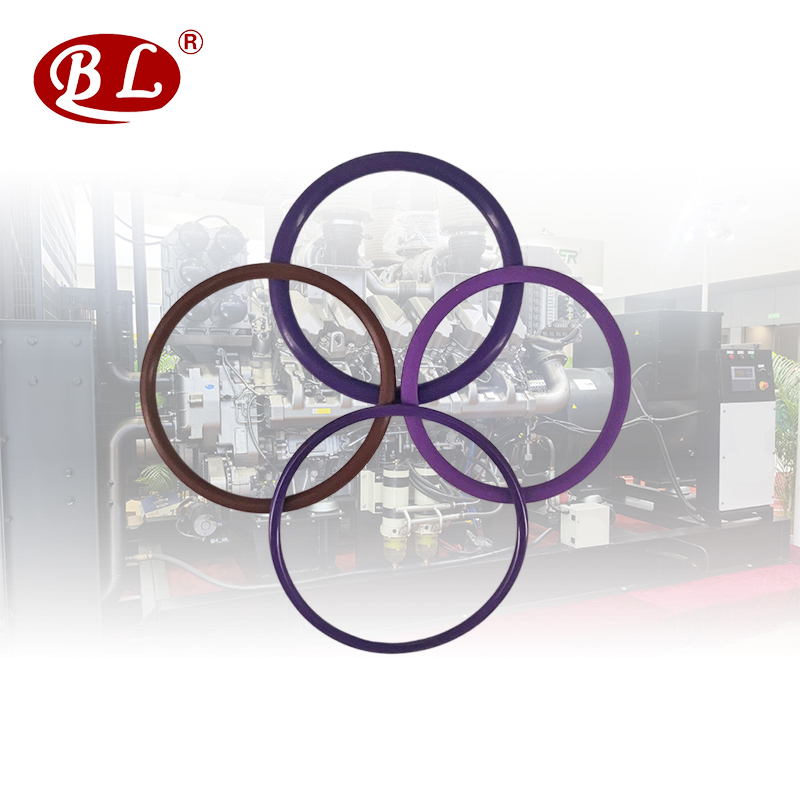

Letlapa la koporo ke sehlahisoa se entsoeng ka bokhabane, se entsoeng ka mokhoa o nepahetseng sa boleng bo ikhethang. Li-gasket tsa Copper li sebelisoa haholo litiisong tse fapaneng tsa pompo ea oli ho netefatsa ts'ebetso e nepahetseng ea ho tiisa le ho phela nako e telele. Ho feta moo, ka lebaka la thepa ea eona e matla ea mochine, botsitso ba nako e telele, le ho hanyetsa ho hoholo ha kutu, brass gasket ke e 'ngoe ea lisebelisoa tse molemohali tse ka sebelisoang ho hlahisa litiiso tsa pompo ea oli.

Ho netefatsa hore sehlahisoa se seng le se seng se khotsofatsa litlhoko tse thata, lipampiri tsa rona tsa koporo li etsoa ka mokhoa o nepahetseng haholo. Ho etsa bonnete ba hore letlapa le leng le le leng la koporo le letlapa la koporo le ka khotsofatsa litebello tsa bareki ba rona, re hatisa haholo theknoloji ea tlhahiso le taolo ea boleng.

Re na le taolo e eketsehileng holim'a litšenyehelo tsa tlhahiso le boleng hobane ke sehlahisoa se entsoeng lapeng. Re sebelisa lisebelisoa tsa morao-rao tsa tlhahiso le theknoloji hammoho le sistimi e thata ea taolo ea boleng ho netefatsa hore sehlahisoa se seng le se seng se ka khotsofatsa litebello tsa bareki.

Re etsa mefuta e fapaneng ea litiiso tsa pompo ea oli, ho kenyelletsa le mehele ea ho koala pompo ea oli, ho kenyelletsa le li-gasket tsa koporo le tsa koporo. Bareki ba bangata ba amohetse le ho tšepa lihlahisoa tsa rona, tse sebelisoang haholo indastering ea likoloi, ea mechini le ea boenjiniere. Boitlamo ba rona bo itšetlehile ka ho fa bareki ba rona thepa le litšebeletso tse phahameng. Ntle le boleng ba sehlahisoa, re boetse re nahana ka litlhoko le ho kenya letsoho ha bareki ba rona. Re ikemiselitse ho sebelisana haufi-ufi le bareki ho hola le ho tsoela pele re le sehlopha.

Ka bokhutšoanyane, lipampiri tsa rona tsa koporo ke khetho ea hau e tšepahalang. Re tla tsoelapele ho sebetsa ka thata ho tsoela pele ho ntlafatsa boleng ba sehlahisoa le boemo ba thekenoloji, le ho theha boleng bo boholo ho bareki ba rona. Ke labalabela ho sebetsa le uena!

Haeba o hloka thuso efe kapa efe ea sehlahisoa kapa tšehetso ea sehlahisoa, re thabela ho fana ka eona. Joaloka k'hamphani e shebaneng le boqapi ba theknoloji le boleng ba sehlahisoa, re lula re ikemiselitse ho theha lihlahisoa tse bolokehileng, tse tšepahalang le tse holimo bakeng sa bareki ba rona.